titanium seamless tubes & pipes

Contact Person : Mr Joe Jin

Phone Number : +86 18621799451

WhatsApp : 0086 18621799451

Detail Information

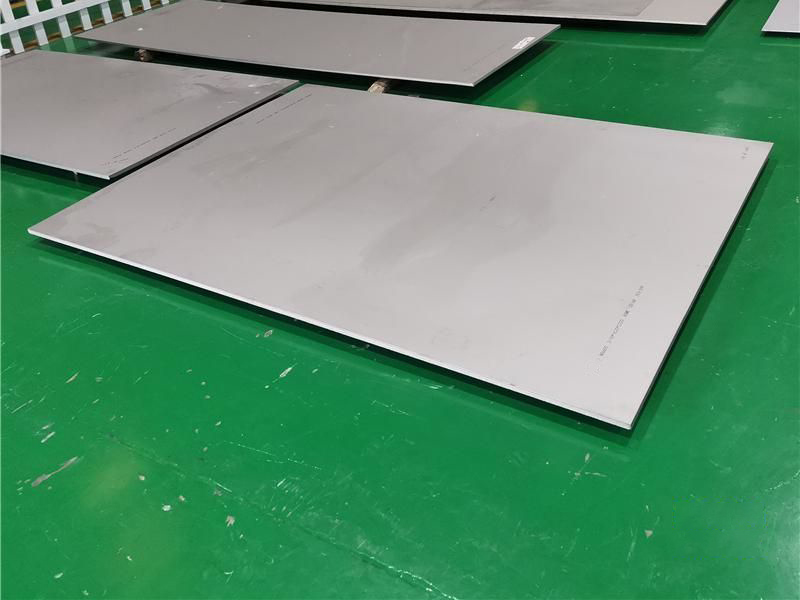

Product Description

Grade: Alloy 625 /N06625 , Alloy 600 /N06600 ,Alloy 601 /N06601 , Alloy 718 /N07718, Alloy C276 /N10276 , Alloy 800 /N08000 , Alloy 825 /N08825 , Alloy 400 /N04400,etc

Standard: ASTM B168; ASTM B443; ASTM B670; ASTM B127;ASTM B162; ASTM B333; ASTM B575; ASTM B582; , etc

Surface: Bright Annealed

Technology: Cold Rolled

NDT: Ultrasonic test; Penetrant Test

Inspection: 100%

Packing: Pallet/Plywooden case

Quality Assurance: ISO & PED

|

Sheet |

Plate |

Strip |

|

|

Thickness |

<6mm |

≥6mm |

0.15mm-3mm |

|

Width |

≤1200mm |

≤2800mm |

≤1000mm |

|

Length |

≤3000mm |

≤8000mm |

As customer’s requirement |

Alloy C276 Chemical composition:

|

% |

Ni |

Cr |

Mo |

Fe |

W |

Co |

C |

Mn |

Si |

P |

S |

V |

|

min |

balance |

20.0 |

12.5 |

2.0 |

2.5 |

- |

- |

- |

- |

- |

- |

- |

|

max |

22.5 |

14.5 |

6.0 |

3.5 |

2.5 |

0.015 |

0.50 |

0.08 |

0.020 |

0.020 |

0.35 |

Features: Alloy C-276 has excellent resistance to localized corrosion, stress corrosion cracking, and to both oxidizing and reducing media, thus making it suitable for a wide variety of chemical process environments, including ferric and cupric chlorides, hot contaminated media (organic and inorganic), formic and acetic acids, seawater and brine solutions. It is one of the few materials that withstands the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide.

Applications: Chemical processing, waste treatment, pollution control, pulp and paper production, and marine engineering.

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Iron case; woven bag or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

| Quality | Test | NTD(Ultrasonic test, Eddy Current test); |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature); | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |