titanium seamless tubes & pipes

Contact Person : Mr Joe Jin

Phone Number : +86 18621799451

WhatsApp : 0086 18621799451

Detail Information

Product Description

Nickel 200 is commercially pure wrought nickel. It is highly resistant to various reducing chemicals. It can also be used in oxidizing conditions that cause the formation of a passive oxide film, for instance its unexcelled resistance to caustic alkalis. Nickel 200 is limited to service at temperatures below 315℃, because at higher temperatures it suffers from graphitization which results in severely compromised properties.

|

Grade |

Alloy 201/N02200, Alloy 200/N02200, Alloy 625 /N06625 , Alloy 600 /N06600 ,Alloy 601 /N06601 , Alloy 718 /N07718, Alloy C276 /N10276 , Alloy 800 /N08000 , Alloy 825 /N08825, Alloy 400 /N04400,etc |

|

Standard |

ASTM B168; ASTM B443; ASTM B670; ASTM B127;ASTM B162; ASTM B333; ASTM B575; ASTM B582; , etc |

|

Surface |

Bright Annealed |

|

Technology |

Cold Rolled |

|

NDT |

Ultrasonic test; Penetrant Test |

|

Inspection |

100% |

|

Packing |

Pallet/Plywooden case |

|

Quality Assurance |

ISO & PED |

|

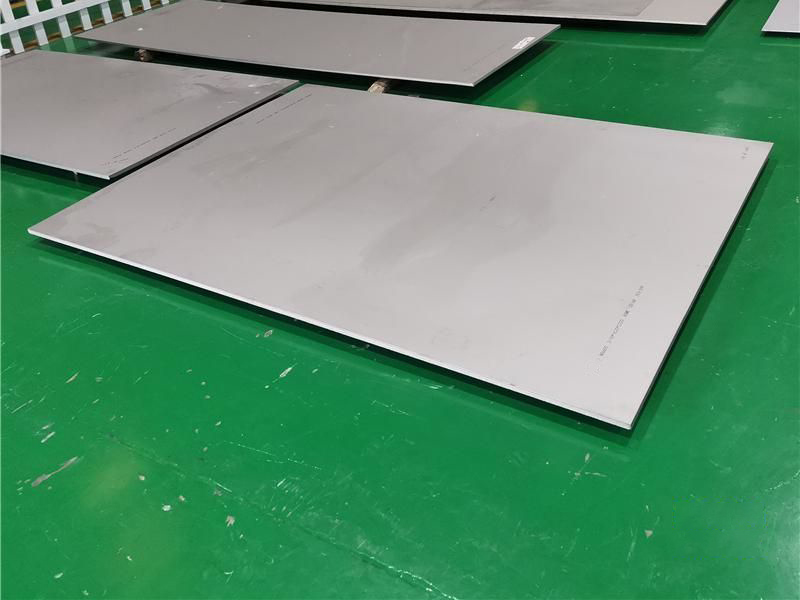

Sheet |

Plate |

Strip |

|

|

Thickness |

<6mm |

≥6mm |

0.15mm-3mm |

|

Width |

≤1200mm |

≤2800mm |

≤1000mm |

|

Length |

≤3000mm |

≤8000mm |

As customer’s requirement |

Features: Nickel 200 is commercially pure wrought nickel. It is highly resistant to various reducing chemicals. It can also be used in oxidizing conditions that cause the formation of a passive oxide film, for instance its unexcelled resistance to caustic alkalis. Nickel 200 is limited to service at temperatures below 315℃, because at higher temperatures it suffers from graphitization which results in severely compromised properties. In that circumstance, Nickel 201 is used instead. It has a high Curie temperature and good magnetostrictive properties. Its thermal and electrical conductivities are higher than nickel alloys.

Applications: Useful for applications where maintaining product purity is considered such as handling of caustic alkalis, foods and synthetic fibers; electrical and electronic parts; aerospace and missile components; and chemical storage and shipping tanks

Nickel 200 Chemical composition

|

% |

Ni |

Fe |

C |

Mn |

Si |

S |

Cu |

|

min |

99 |

||||||

|

max |

0.4 |

0.15 |

0.35 |

0.35 |

0.01 |

0.25 |

Nickel 200 Physical properties

|

Density |

8.89 g/cm3 |

|

Melting range |

1435-1446℃ |